Challenge are already a trusted supplier for numerous waste and recycling plants due to consistently delivering high quality products, reductions in expenditure and lowering stores inventories. This is accomplished by managing our own internal supply lines to ensure that the required products are available when needed while also working with each plant to achieve a tailored solution that works for them.

A key area where cost savings can be significant is by fitting a Challenge baling belt onto existing machines. Not only are these belts fully compatible with the existing machine without any modification, they are manufactured from harder wearing steel, are fully robotically welded and are manufactured in accordance with our ISO9001:2015 manufacturing certification. Production baler belts that have worked until the end of their service lives have, on average, reduced purchase costs by as much as 50% while increasing the number of bales processed before replacement by up to 33%.

Many of our customers have also taken advantage of site visits from one of our qualified engineers which provide a written report on the current baler and associated machinery conditions. This has assisted plants in preventative maintenance planning while also seeing cost savings for every bale that they process.

Challenge are able to supply the following spares;

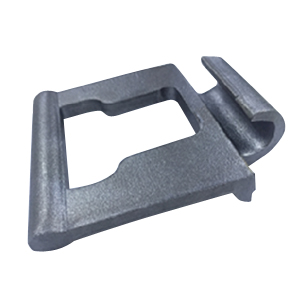

- Direct replacement baling belt for both the infeed and main baling chamber. A fully proven and improved design offering a longer life compared to the OEM belts at a reduced cost. Fitted with end bearing assemblies and supplied with a male grease nipple for each bearing assembly housing.

- All belts are manufactured in our own production plant using the latest manufacturing methods and robotic welding to ISO9001:2015. All belts are fully inspected prior to being securely packed for despatch.

Baling Belt

- Complete replacement kit containing the main spherical roller bearing, spacer, seal, end plate and retaining circlip for use on all belts.

Belt End Bearing Assemblies

- Forged from high quality steel for increased working loads compared to cast versions.

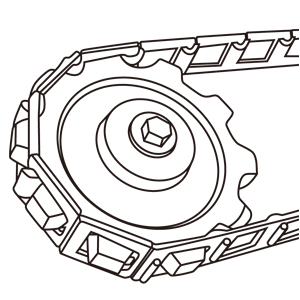

Detachable Link Chain

- Precision sprockets to suit cast detachable link chain. Available with a variable number of teeth and bore size depending upon the conveyor.

Detachable Link Chain Sprockets

- Heavy duty spin riveted chain for tough applications, with shot peened high fatigue resistance link plates to mitigate shock loading.

Drive/Transmission Chain

- High accuracy, machine cut, medium carbon steel sprockets from sawn and forged block steel.

- Available with taper and pilot bores as standard.

Drive/Transmission Sprockets

- Imperial and metric conveyor chains with attachments or bespoke chains to customer designs, manufactured in high quality steels with the latest machining centres to ISO9001:2015.

Conveyor Chain

- Machine cut, medium carbon C45 conveyor chain sprockets with optional flame hardened teeth and a wide range of shaft attachment options.

Conveyor Chain Sprockets

- EN8 pins with hardened alloy bushes to directly replace the main chambers external belt gearings pins and bushes.

- We are also able to offer full drive wheel assemblies.

Paddle Pins, Hardened Bushes & Drive Wheel Assemblies

- Bearing rings and balls manufactured from GCr15 high carbon chromium bearing steel.

- Available in common metric and imperial sizes.

Standard Bearings

- Sealed with triple lip seals as standard with an external grease nipple for a longer life.

- Available in UCF200 and UCFX 00 from 3/4" up to 3" diameter shaft sizes.

4 Hole Flanged Bearings

- Sealed with triple lip seals as standard with an external grease nipple for a longer life.

- Available in UCP200 and UCPX 00 from 3/4" up to 3" diameter shaft sizes.

Pillow Block Bearings

- 7 different options, including 5 different types of JAW couplings.

- All couplings are available in various hub and bore arrangements including tapered.

Drive Couplings

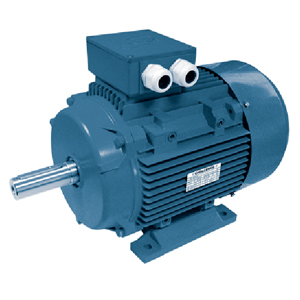

- Challenge offer a range of IEC 60034 motors in frame sizes 56-200 for three phase in IE1, IE2 and IE3.

Electric Motors

- Heavy duty, direct replacement large chamber/caster wheels for running the belt around the outside diameter of the compacting chamber.

Large Diameter Chamber Wheels

- High grade nylon wheels for the internal diameter of the compacting chamber.

- Supplied with or without stainless steel pins.

Small Diameter Chamber Wheels

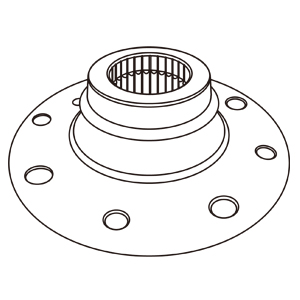

- Precision drive flanges offering direct replacement for the OEM original flanges and are machined from solid alloy steel.

Drive Flanges

*Flexus is the registered trade mark of Flexus Balasystem AB. All brand names and products are registered® by their respective owners. They are used here to show cross-product compatibility and not affiliation with the registered® owners.

Download Compatible Flexus* Balasystem* Spares Flyer (.pdf – opens new window)

Português

Português Français

Français Español

Español 简体中文

简体中文 Deutsch

Deutsch

Product Booklet

Product Booklet